Our 1-axis die spraying manipulators are the perfect fit for small closing forces, simple applications and offer the best price – performance ratio.

They are easy and simple to install, maintain and set up. The vertical axis can be manually adjusted for highest accuracy and rotated for easy change of the die.

The 2-axis sprayers with servo movements are carefully engineered for the harsh environment in the foundry. They guarantee consisted and efficient process and cover the application for DCMs between 380 – 2500 tons closing force.

PRECISE SPRAYING

FAST CYCLES

EXTREME FLEXIBILITY

HIGHLIGHTS

FAST, PRECISE SPRAYING AND MODULAR DESIGN

Our spraying manipulators provide short cycle times on even complex dies. The independent control of each spray and blow circuit ensures that the spraying is carefully controlled.

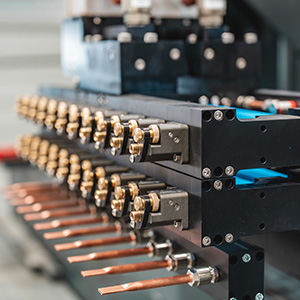

Nozzles and spray heads

With the modular design of our spray heads and nozzles, you can individually configure and expand the spraying tools.

Die spraying robots

We can integrate industrial robots for die spraying application. They are the best solution to achieve consistent, regulated process with a tool on different dies. A simple change from the saved programs will be enough.

TECHNICAL DATA

Please select a device type:

| SPRAYER | SH-1P |

|---|---|

| Drive System | Pneumatic |

| Number of nozzles* – Standard ÷ max to | 2 x 7 |

| Blowing + Spraying circuits – Standard / Optional | 1 + 1 |

| Number of Axes | 1-axis |

| Passive horizontal adjustment [mm] | 190 |

| Passive vertical adjustment [mm] | 50 |

| Vertical stroke [mm] | 650 |

| Vertical velocity [m/s] | 2 |

| Air consumption at coating [l/min] | 104 |

| Air consumption at blowing [l/min] | 140 |

| Liquid Tank [l] | 25 |

| DCM Locking Force [t] | 50 - 80 |

| DCM Type | Hot Chamber |

| SPRAYER | SH |

|---|---|

| Drive System | Servo |

| Number of nozzles* – Standard ÷ max to | 2 x 7 ÷ 2 x 9 |

| Blowing + Spraying circuits – Standard / Optional | 1 + 2 |

| Number of Axes | 1-axis |

| Passive horizontal adjustment [mm] | 360 |

| Vertical stroke [mm] | 800 |

| Vertical velocity [m/s] | 3 |

| Air consumption at coating [l/min] | 56 |

| Air consumption at blowing [l/min] | 87 |

| Liquid Tank [l] | 150 |

| DCM Locking Force [t] | 80 - 315 |

| DCM Type | Cold / Hot Chamber |

| SPRAYER | SC |

|---|---|

| Drive System | Servo |

| Number of nozzles* – Standard ÷ max to | 2 x 9 ÷ 4 х 9 |

| Blowing + Spraying circuits – Standard / Optional | 2 + 2 / 2 + 6 |

| Number of Axes | 1-axis |

| Passive horizontal adjustment [mm] | 360 / 460 |

| Vertical stroke [mm] | 900 |

| Vertical velocity [m/s] | 3 |

| Air consumption at coating [l/min] | 83 |

| Air consumption at blowing [l/min] | 120 |

| Liquid Tank [l] | 150 |

| DCM Locking Force [t] | 130 - 380 |

| DCM Type | Cold Chamber |

| SPRAYER | SM-2 |

|---|---|

| Drive System | AC / Servo |

| Number of nozzles* – Standard ÷ max to | 2 x 8 ÷ 4 x 14 |

| Blowing + Spraying circuits – Standard / Optional | 1 + 2 / 2 + 6 |

| Number of Axes | 2-axis |

| Horizontal stroke [mm] | 1200 |

| Vertical stroke [mm] | 1300 |

| Horizontal velocity [m/s] | 1 |

| Vertical velocity [m/s] | 1 |

| Air consumption at coating [l/min] | 73.5 |

| Air consumption at blowing [l/min] | 115 |

| Liquid Tank [l] | 150 |

| DCM Locking Force [t] | 380 - 640 |

| DCM Type | Cold / Hot Chamber |

| SPRAYER | SM-3 |

|---|---|

| Drive System | AC / Servo |

| Number of nozzles* – Standard ÷ max to | 2 x 12 ÷ 4 x 18 |

| Blowing + Spraying circuits – Standard / Optional | 2 + 6 |

| Number of Axes | 2-axis |

| Horizontal stroke [mm] | 1200 |

| Vertical stroke [mm] | 1500 |

| Horizontal velocity [m/s] | 1 |

| Vertical velocity [m/s] | 0.8 |

| Air consumption at coating [l/min] | 120 |

| Air consumption at blowing [l/min] | 200 |

| Liquid Tank [l] | 150 |

| DCM Locking Force [t] | 640 - 1050 |

| DCM Type | Cold Chamber |

| SPRAYER | SM-4 |

|---|---|

| Drive System | Servo |

| Number of nozzles* – Standard ÷ max to | 2 x 15 ÷ 4 x 19 |

| Blowing + Spraying circuits – Standard / Optional | 2 + 6 |

| Number of Axes | 2-axis |

| Horizontal stroke [mm] | 1900 |

| Vertical stroke [mm] | 1900 |

| Horizontal velocity [m/s] | 0.7 |

| Vertical velocity [m/s] | 0.7 |

| Air consumption at coating [l/min] | 150 |

| Air consumption at blowing [l/min] | 250 |

| Liquid Tank [l] | 150 |

| DCM Locking Force [t] | 1050 - 2500 |

| DCM Type | Cold Chamber |